CNC Servo Hydraulic Press Brake Machine 4+1 Axis

$17,500.00

Type: Electric Hydraulic Servo CNC Press Brake

Model: WE67k-100T/2500

Control system: Laimore EL15T (Smart)

Control axis: 4 axis (Y1,Y2,X,R+Crowning)

Dimension:2800x2200x2500mm

Weight: 6500KG

Category: CNC Press Brake

Estimated delivery:28 days

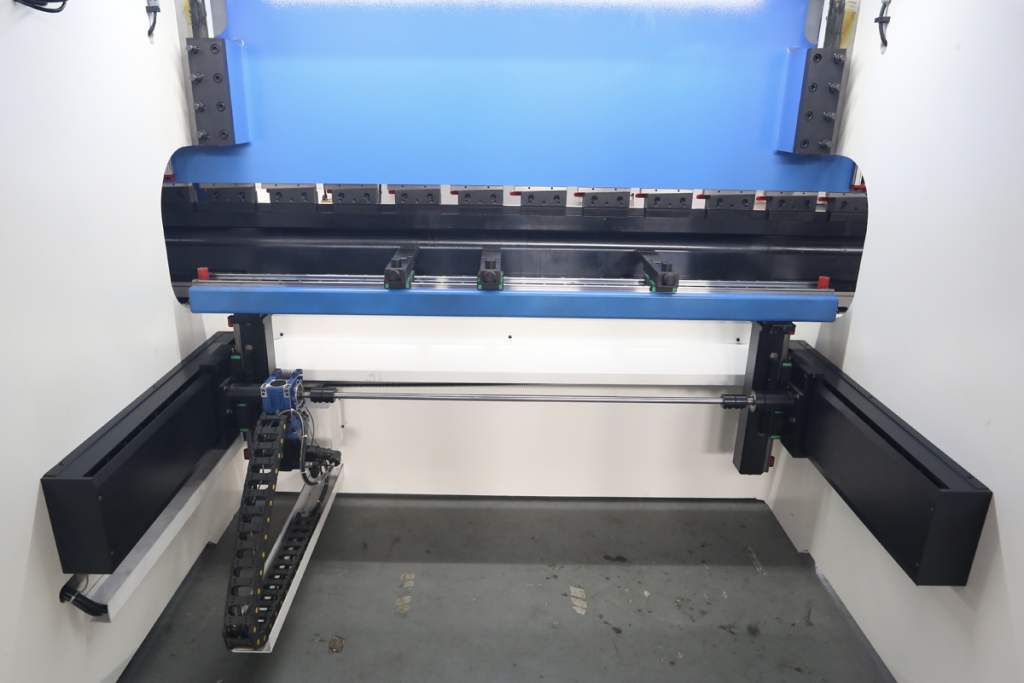

Features CNC Servo Hydraulic Press Brake Machine

- The frame is constructed with a mortise-and-tenon design, fully welded for stability and longevity. It is processed using a large floor-mounted boring and milling machine to ensure high precision and minimize deformation.

- It adopts top-level electro-hydraulic servo valve and grid ruler for closed-loop control.

- The standard configuration features a 2-axis (X,R) back gauge, or you can choose the more versatile and efficient 4-axis (X,R,Z1,Z2) back gauge as an alternative option.

- The worktable is equipped with a motorized CNC controlled anti-deflection mechanism that effectively eliminates the impact of slider deformation on workpiece quality. The CNC system automatically adjusts compensation amount for convenient and precise operation.

Standard specification

EL15T control system

- Flexible programming

You can choose three modes - Data product programming

The process information of a singleproduct is displayed in a list. All data canbe displayed on one page, and the curveinformation can be modified more quickly - Graphic product programming

Easy to use 2D graphics programming,the system automatically calculates thebending process, real-time intuitive, novicecan quickly get started. - Special programming for tuningmachines

For the detailed setting of single channelbend, easy bend can also be set quicklyusing this programming mode.

INOVANCE main servo motor

- Advanced control algorithm: INOVANCE main servo motor adopts advanced control algorithm, which can realize precise control of the position, speed and acceleration of the motor.

- High-precision encoder feedback: Equipped with a high-precision encoder feedback system, which further improves the control accuracy and response speed of the motor, ensuring the accuracy and stability of the bending process.

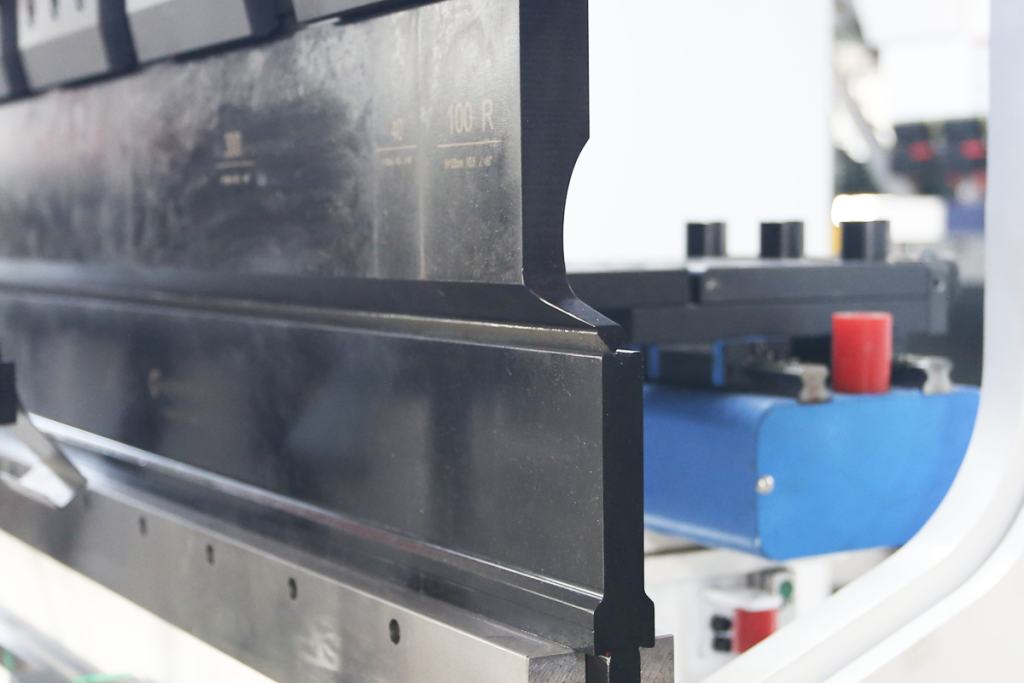

Fast clamp

- Fast clamp will help you replace the top punch in very shortly time, Fast intermediate loading and up loading function to improve work efficiency

Mechanical Crowning

- The motorized crowning system will adjust the parallelism and straightness automatically

Can be controlled by EL15T controller

Press Brake 2-Axis CNC BackGauge with X, R-Axis

- Hiwin Ball screws and linear guide on X, R-axis

- Axis X speed 500 mm/s

- Manual Z1, Z2-axis with HIWIN linear guide

- Mechanical accuracy ± 0.01 mm

- Fingers with double stop and micro metric adjustment

Press Brake Tools

- The upper and lower Tools are made of high-quality tools steel (such as Cr12MoV) and undergo forging, turning, and milling processes.

- The Tools are subjected to quenching, tempering, and other heat treatment processes to enhance hardness and wear resistance.

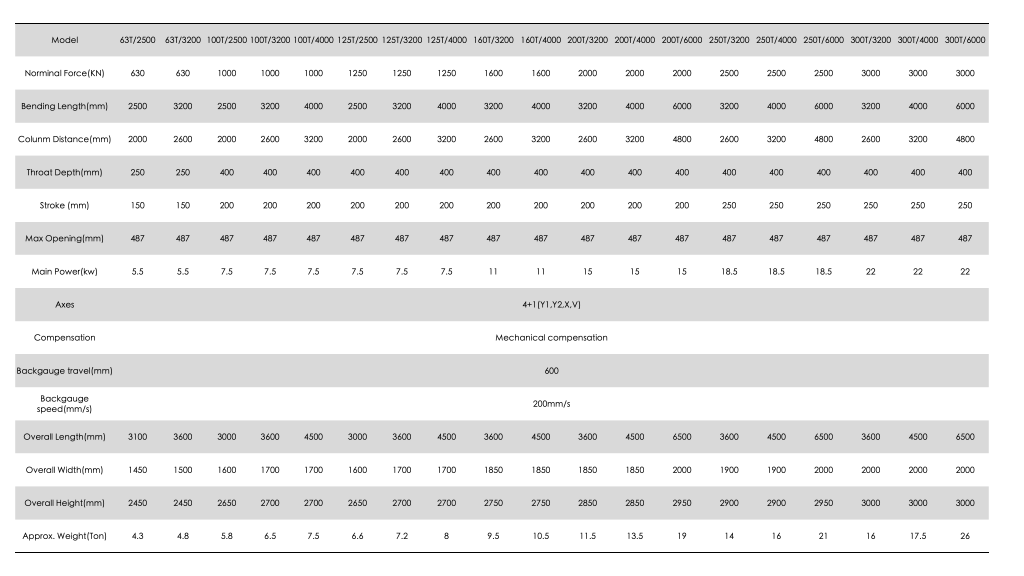

Technical Specification

Optional Configuration

DA66T CNC Controller

- 2D graphical touch screen programming mode

- 17″ high resolution colour TFT

- Full Windows application suite

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control’s multitasking environment

- Sensor bending & correction interface

- Profile-TL offline software

Laser Protector

- DSP laser safety protection device fully protects the personal safety of the bending machine operator and avoids the danger caused by the fast movement of the slide block on the machine tool.

Packing and delivery

Be the first to review “CNC Servo Hydraulic Press Brake Machine 4+1 Axis” Cancel reply

CNC Press Brake Machine With D...

$38,000.00

Genius CNC Servo Press Brake 6...

$110,000.00

Reviews

There are no reviews yet.