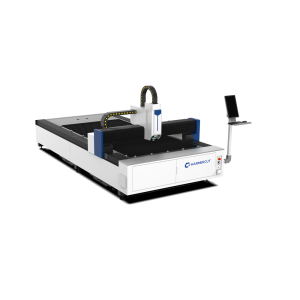

Steel Tube Laser Cutting Machine

$20,715.00

Type: Steel Tube Laser Cutting Machine

Model: T6020

Control system: CYPCUT

Weight: 3150kg

Category: Fiber Laser Cutting Machine

Estimated delivery:28 days

Standard specification

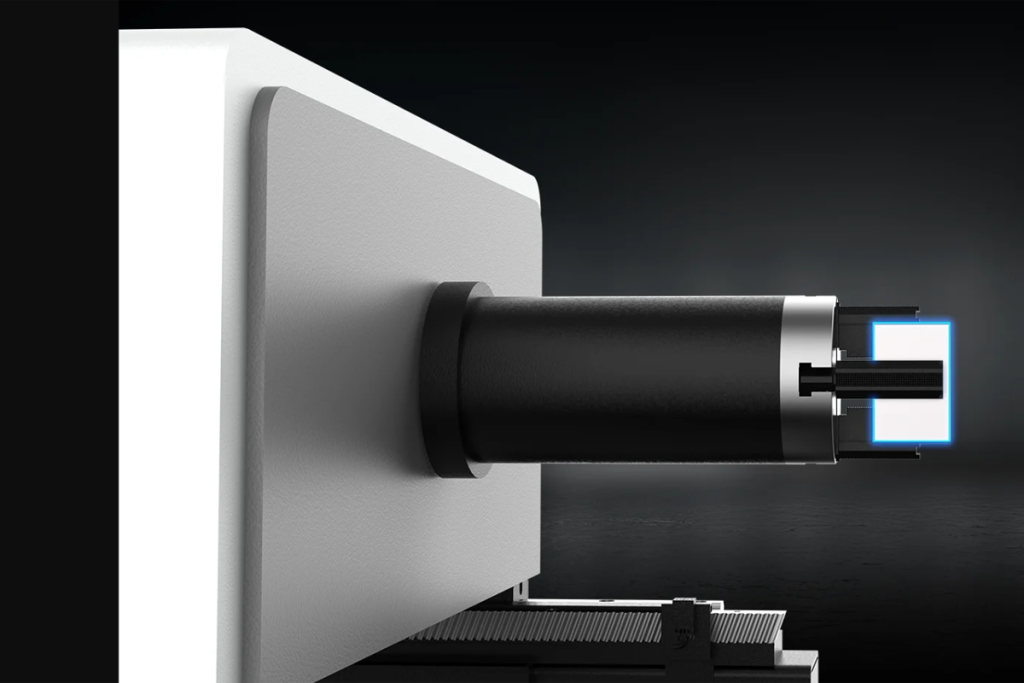

Raytools Auto Focus Tube Cutting Head

- Modular design with easy maintenance.

Dual water cooling circuits. - Auto focus to reduce human intervention and improve piercing and cutting efficiency.

- 3 Cover glasses (top, middle and bottom) to protect collimation & focus lens.

- IP65 class dustproof, patented cover glass cover plate. All-around dust prevention.

- Skinny nozzle structure to decrease interference.

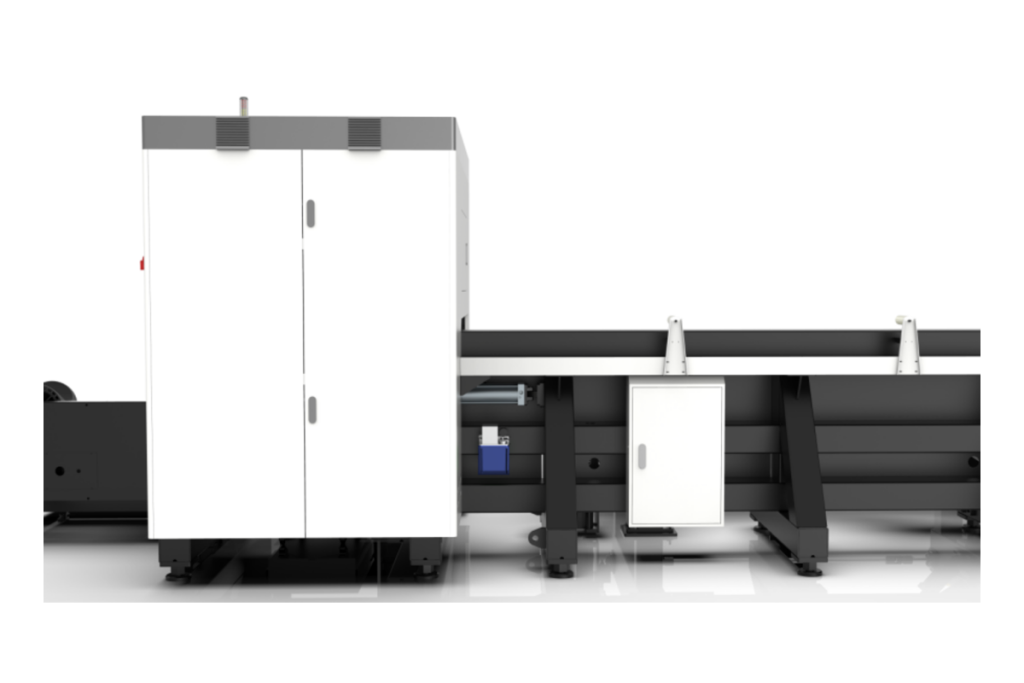

Side-mounted bed structure

- Side-mounted bed, triangular frame structure, with high load-bearing capacity, solid and stable, smooth and stable cutting at high speed, good shock resistance, strong load-bearing capacity and high rigidity and hardness.

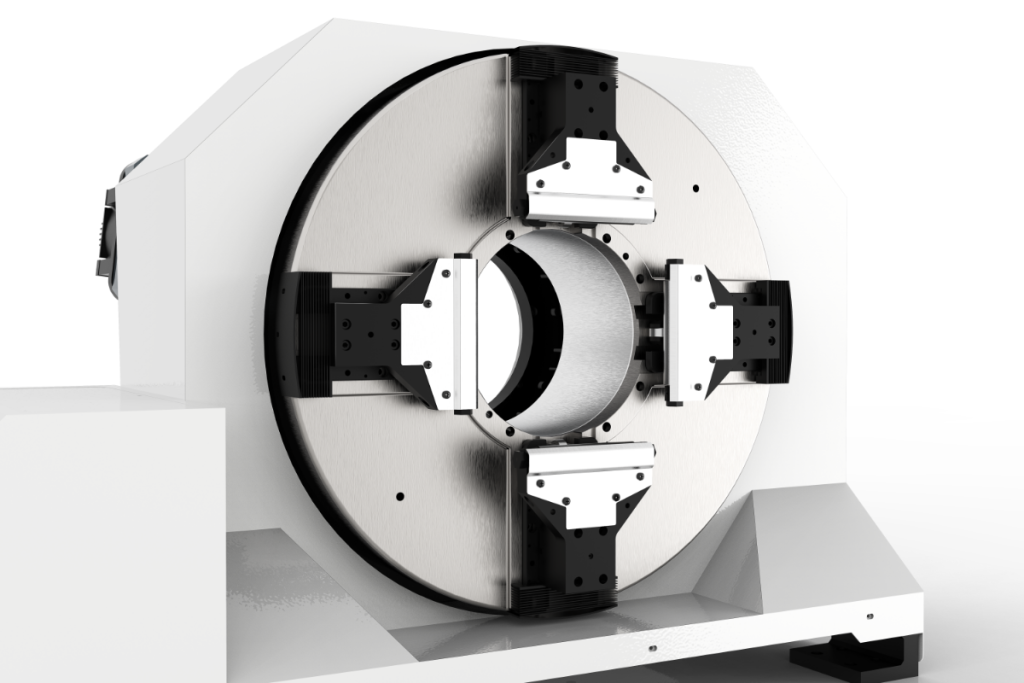

Intelligent Pipe Cutting System

- The cutting software is intelligent, convenient, and efficient. Combined with professional nesting software and a comprehensive process database, it saves time, materials, and worry. It supports processing a variety of profiles, including round, square, track, and oval pipes, angle steel, and channel steel.

High-speed cutting, ultimate processing

- High operating speeds reduce non-productive time and help users increase productivity.

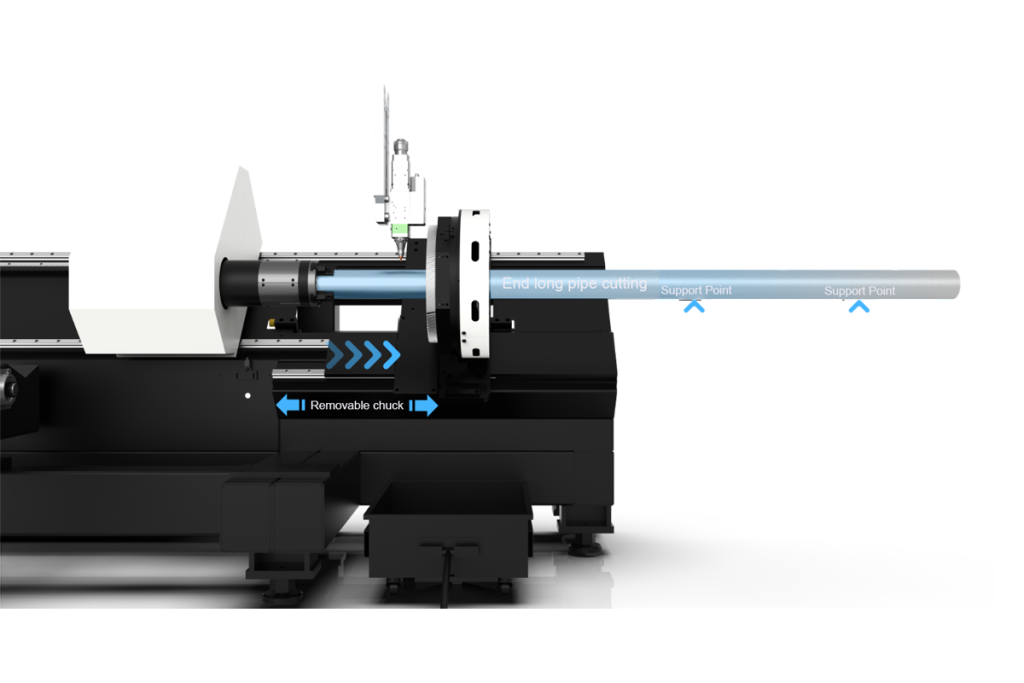

Cost-effective, extremely short tails

- When cutting the end of a pipe, two cutting modes, front clamp avoidance and front clamp movement, achieve extremely short tails and save costs.

Cutting long pipes at the end with high precision and minimal restrictions.

- The removable front chuck design allows the cutting head to rest between the two chucks, effectively cutting longer pipes. The pipe support is more rational and stable, resulting in higher cutting accuracy.

Gas and electricity separation for safe design

- The equipment’s oil, electricity, and gas circuits are separated for independent transmission and transportation, ensuring safe, stable, and reliable operation without interfering with each other.

Optional Configuration

2-3 meter unloading rack

- Combined with the front card transfer function, an optional 2-3 meter unloading rack is available for cutting longer finished materials.

Fully automatic loading system

- The optional fully automatic loading unit frees up manpower, enabling intelligent processing and improving production efficiency.

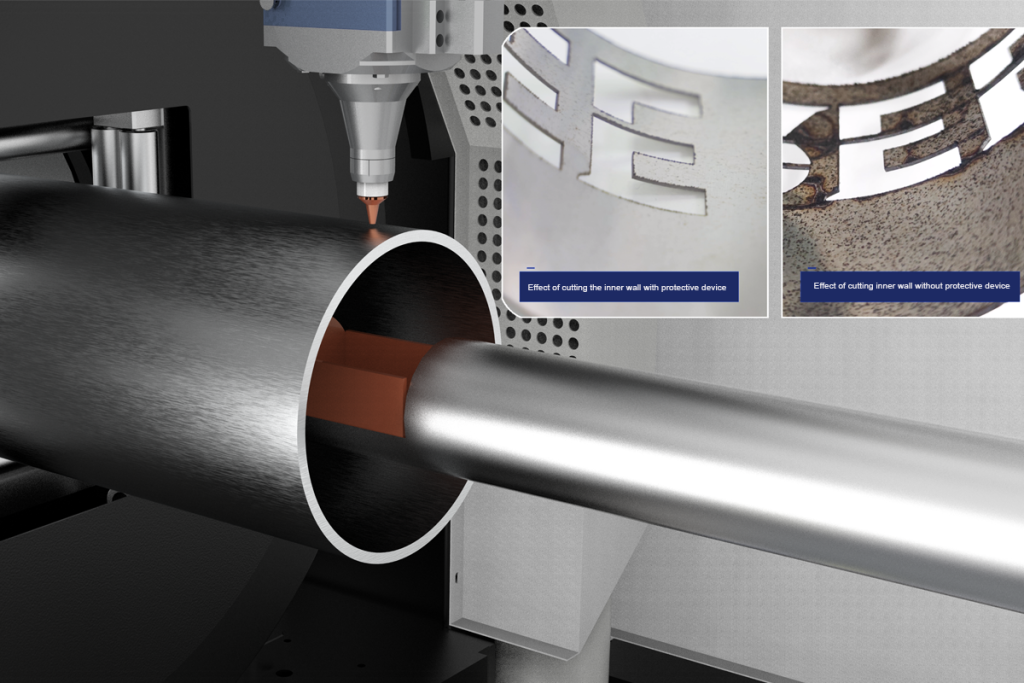

Inner wall protection device

- The optional inner wall protection device ensures a smooth, slag-free inner wall of the pipe during cutting. This allows for one-step forming, reducing processing steps, saving labor and time, and improving production efficiency.

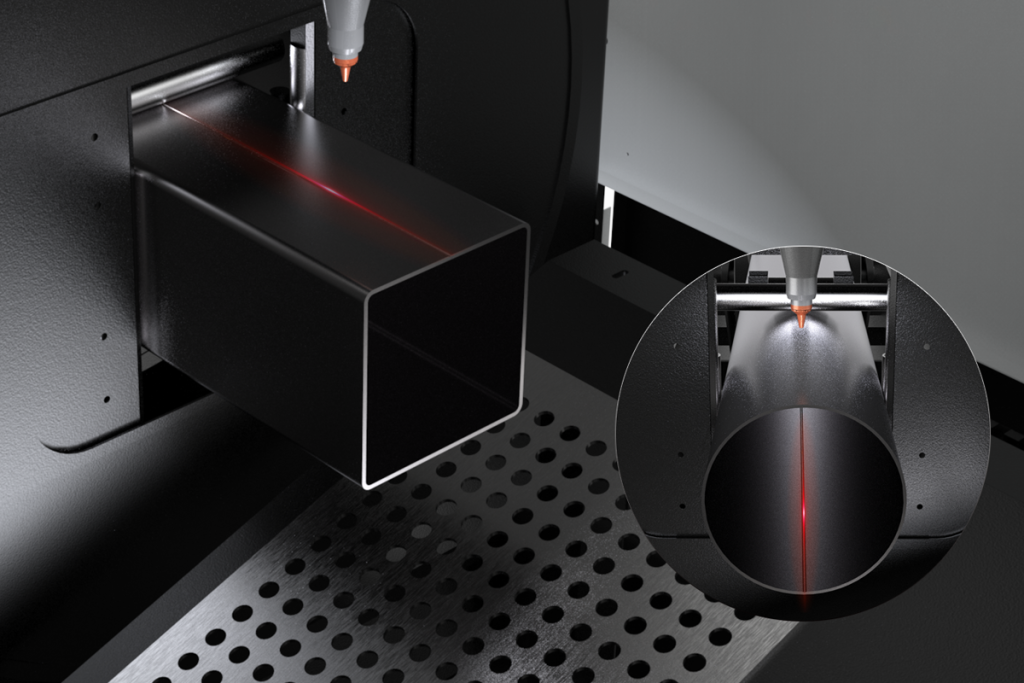

Weld seam recognition

- By adding a camera photo upload function, the system compares the uploaded photo to identify the weld seam location, allowing you to display the weld seam wherever you want.

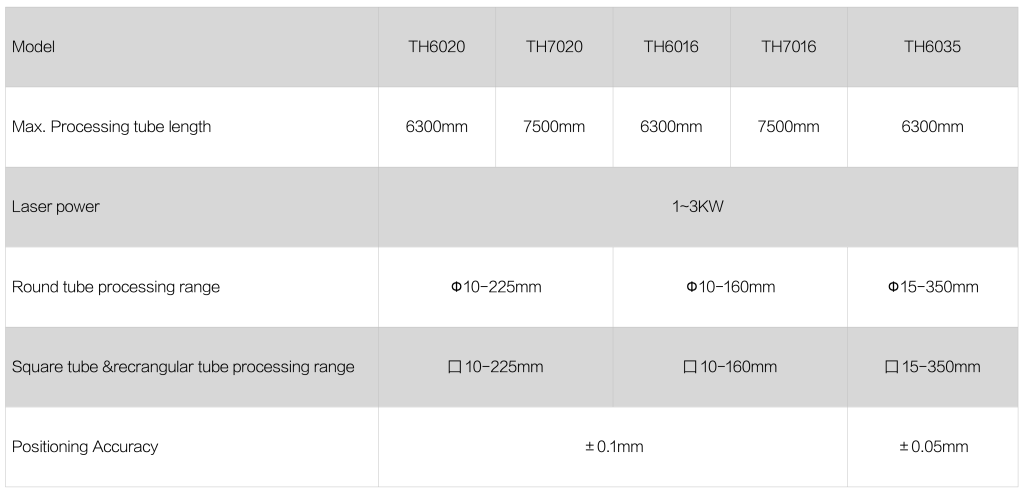

Technical Data

Packing and delivery

Be the first to review “Steel Tube Laser Cutting Machine” Cancel reply

Handheld Laser Welding Machine

$2,857.00

Steel Pipe Laser Cutting Machi...

$22,857.00

Reviews

There are no reviews yet.