تم إضافة "آلة قص الصفائح المعدنية الهيدروليكية" إلى سلة مشترياتك. عرض عربة التسوق

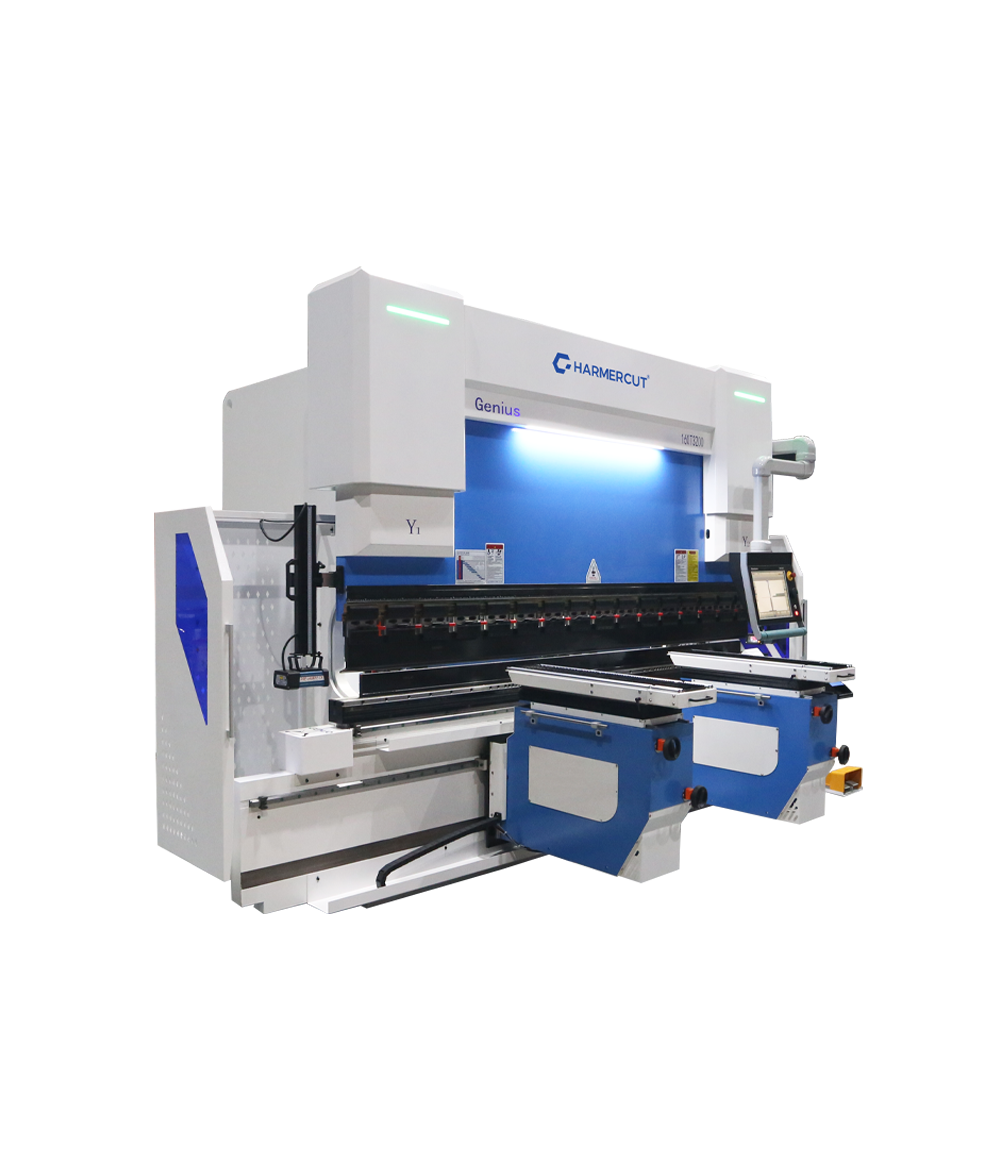

مكبس ثني Genius CNC Servo ذو 6 محاور + 1 مع فحص بالليزر

$110,000.00

يكتب: مكبس الفرامل CNC Genius

نموذج: WE67k-160T/3200

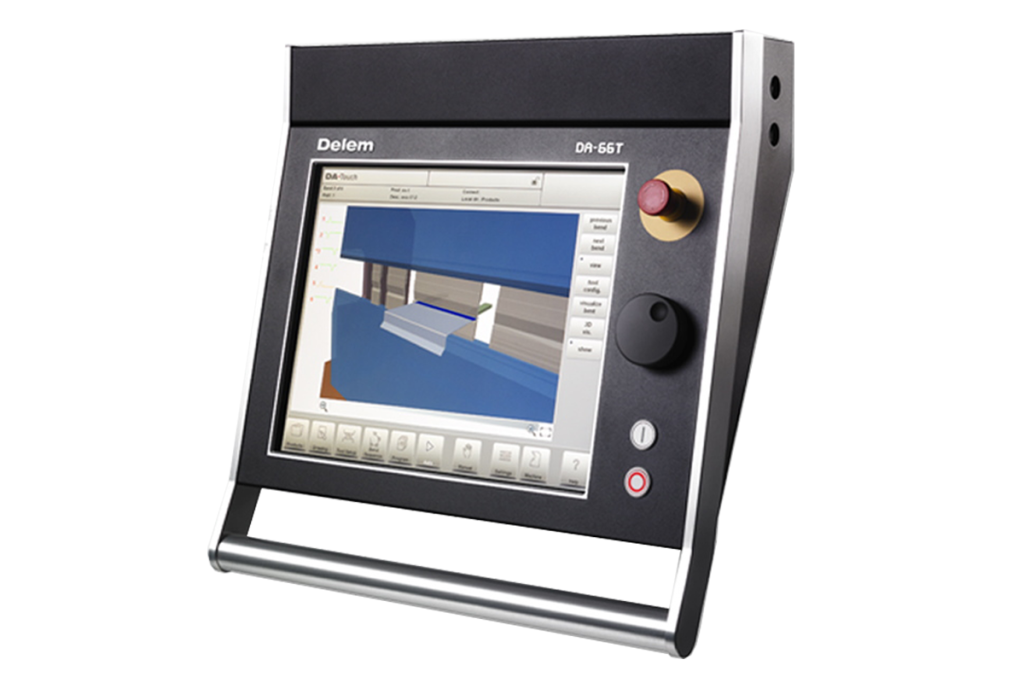

نظام التحكم: DA66T (ذكي)

محور التحكم: 4 محاور (Y1، Y2، X، R، Z1، Z2 + التتويج)

البعد:2800 × 2200 × 2500 مم

وزن: 6500 كجم

فئات: مكابس الضغط CNC

التسليم المتوقع:49 أيام

المواصفات القياسية

وحدة تحكم CNC DA66T

- وضع برمجة شاشة اللمس الرسومية ثنائية الأبعاد

- شاشة TFT ملونة عالية الدقة مقاس 17 بوصة

- مجموعة تطبيقات Windows الكاملة

- توافق Delem Modusys (قابلية التوسع والتكيف للوحدات النمطية)

- USB، واجهة محيطية

- دعم التطبيقات المخصصة للمستخدم ضمن بيئة تعدد المهام الخاصة بعنصر التحكم

- واجهة انحناء المستشعر وتصحيحه

- برنامج Profile-TL غير المتصل بالإنترنت

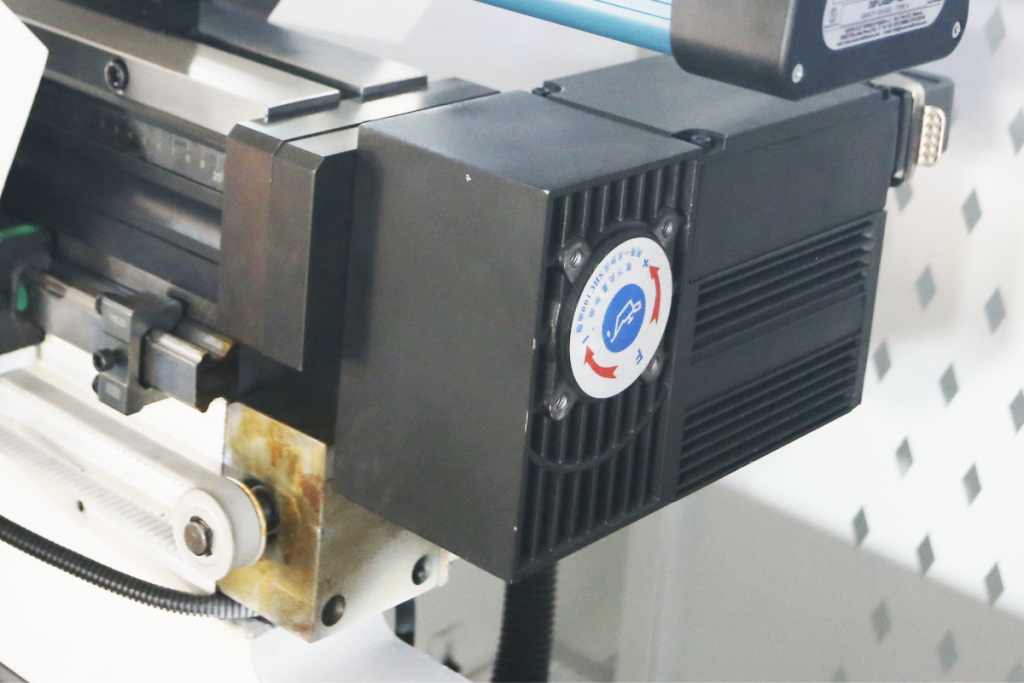

محرك سيمنز

- محرك العلامة التجارية الألمانية الشهيرة يحسن عمر الماكينة ويحافظ على تشغيل الماكينة في بيئة منخفضة الضوضاء

متابعو الورقة

- مُتابعان قابلان للبرمجة يُعززان الصفيحة أثناء الثني. يُلامسان الصفيحة تمامًا، مما يمنع ترهلها.

قياس زاوية الانحناء

- Lasercheck أداة لقياس زاوية الانحناء. هذه الأداة المبتكرة لا تزيد من الدقة فحسب، بل تُبسط أيضًا عملية الانحناء بأكملها. استخدام Lasercheck يُقلل الأخطاء بشكل كبير ويُحسّن جودة المشروع.

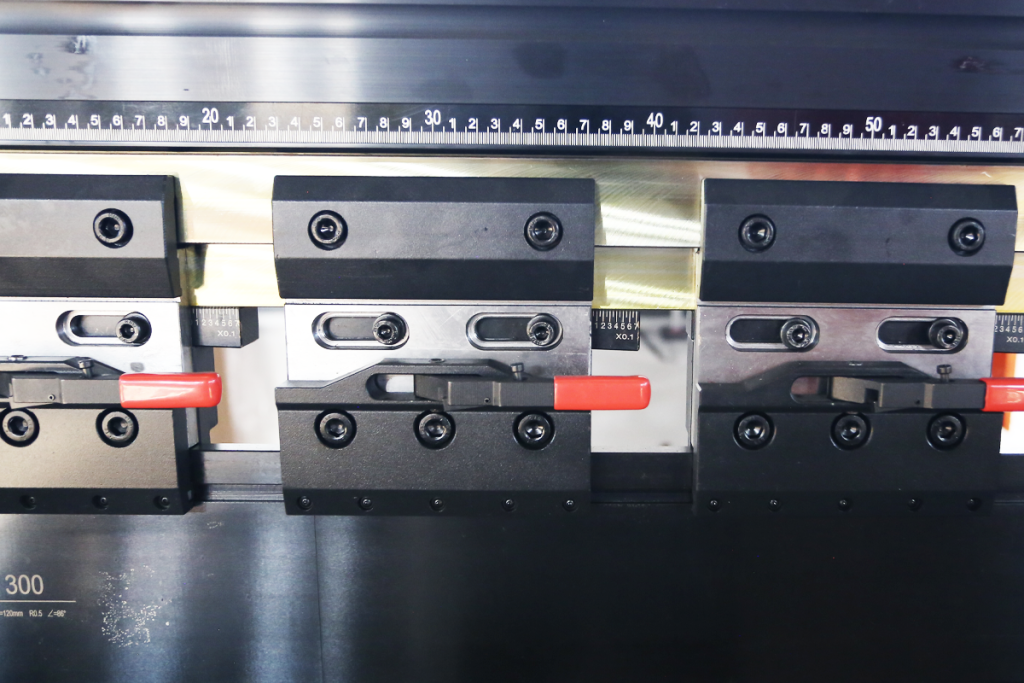

المشبك السريع

- سيساعدك المشبك السريع على استبدال اللكمة العلوية في وقت قصير جدًا، ووظيفة التحميل المتوسط السريع والتحميل العلوي لتحسين كفاءة العمل

التتويج الميكانيكي

- يمكن التحكم في نظام التاج الآلي تلقائيًا عن طريق وحدة تحكم CNC، حيث يقوم بضبط التوازي والاستقامة.

مكبس ثني CNC رباعي المحاور مع مقياس خلفي CNC مزود بمحاور X و R و Z1 و Z2

- براغي الكرة من Hiwin ودليل خطي على المحور X وR Z1 وZ2

- سرعة المحور X 500 مم/ثانية

- وحدة تحكم ميكانيكية للمحور Z1 و Z2 بنظام CNC مع دليل خطي HIWIN

- الدقة الميكانيكية ± 0.01 مم

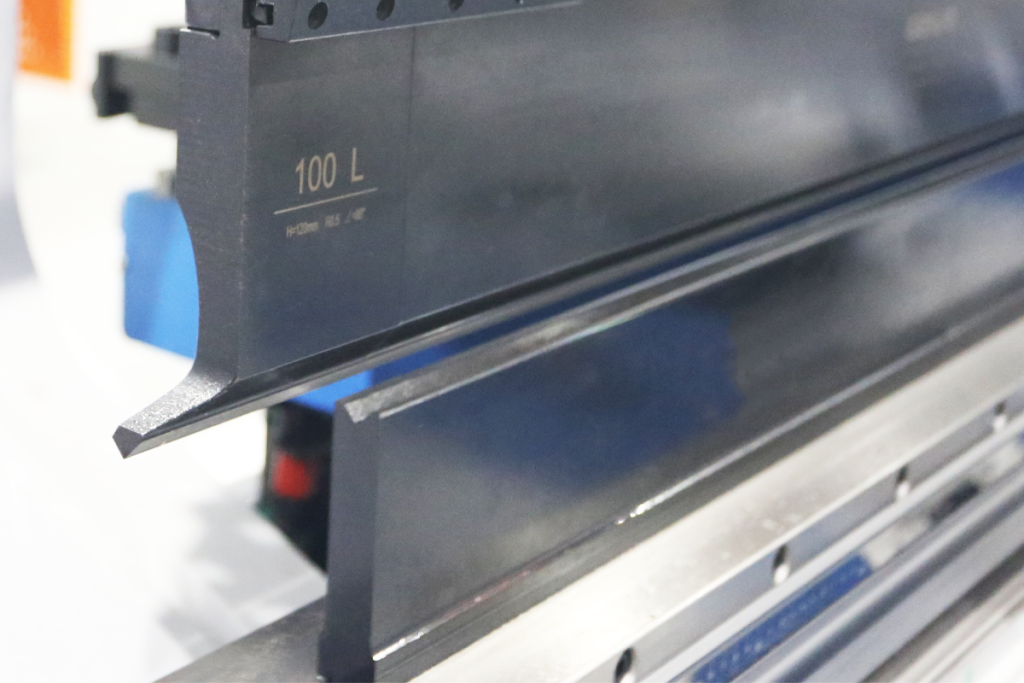

أدوات مكابح الضغط

- يتم تصنيع الأدوات العلوية والسفلية من فولاذ الأدوات عالي الجودة (مثل Cr12MoV) وتخضع لعمليات التشكيل والتحويل والطحن.

- يتم إخضاع الأدوات لعمليات التبريد والتلطيف والمعالجة الحرارية الأخرى لتعزيز صلابتها ومقاومتها للتآكل.

واقي الليزر

- يوفر جهاز حماية الليزر DSP حماية كاملة للسلامة الشخصية لمشغل آلة الانحناء ويتجنب الخطر الناجم عن الحركة السريعة لكتلة الشريحة على أداة الماكينة.

الحماية الكهروضوئية

- الوظيفة الأساسية لجهاز الحماية الكهروضوئية خلف آلة الانحناء هي تشغيل إيقاف التشغيل الطارئ للمعدات على الفور عندما يدخل جسم (مثل الأطراف البشرية) إلى منطقة الخطر الخلفية أثناء تشغيل المعدات، وبالتالي منع الحوادث الأمنية بشكل أساسي مثل الضغط والاصطدام.

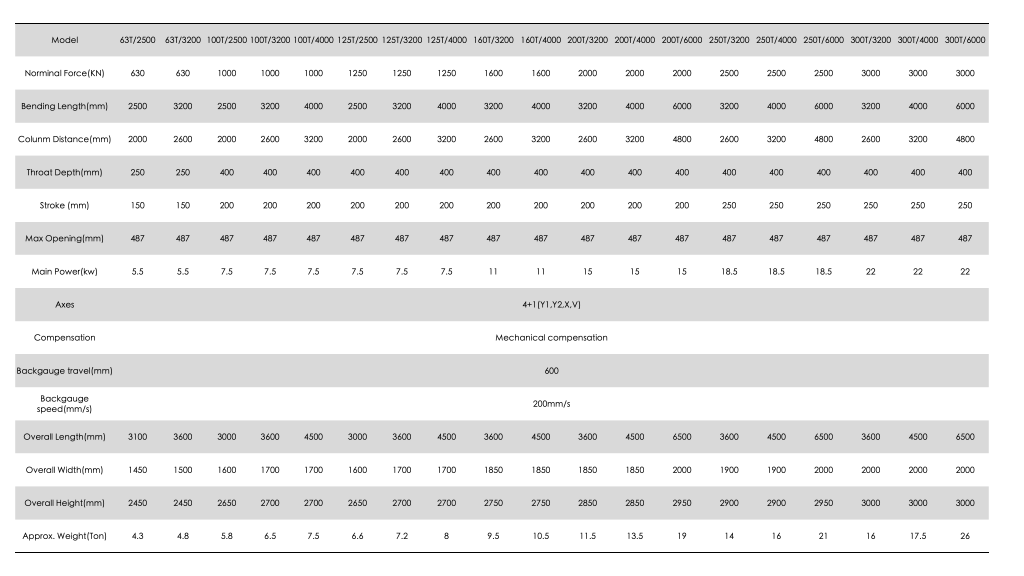

المواصفات الفنية

التكوين الاختياري

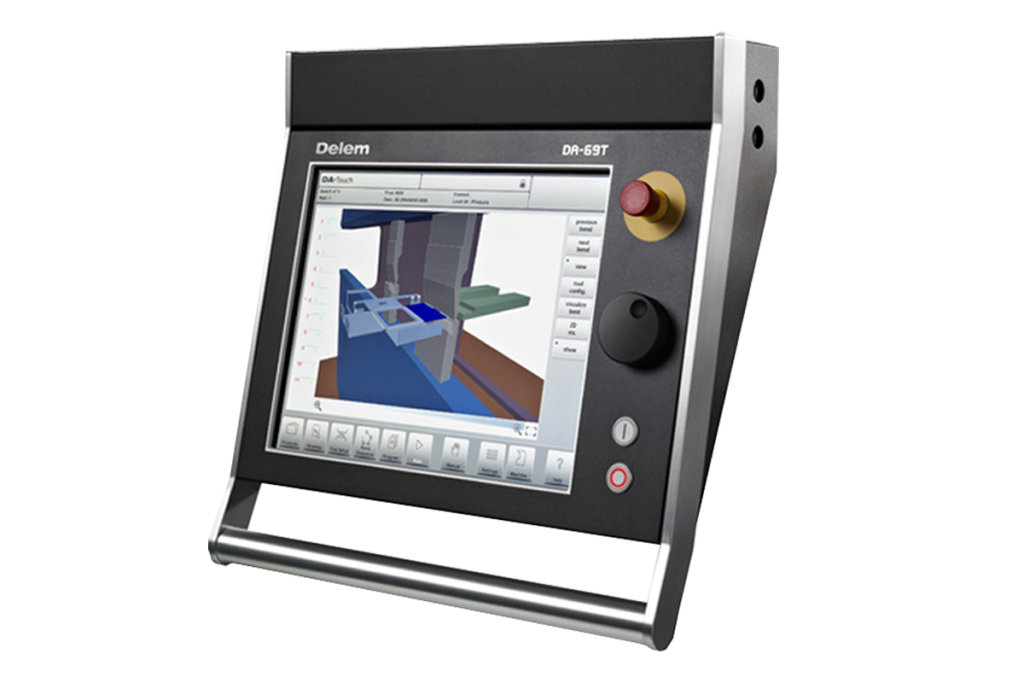

نظام DA69t

- وضع برمجة شاشة اللمس الرسومية ثلاثية الأبعاد وثنائية الأبعاد

- التصور ثلاثي الأبعاد في المحاكاة والإنتاج

- شاشة TFT ملونة عالية الدقة مقاس 17 بوصة

- مجموعة تطبيقات Windows الكاملة

- توافق Delem Modusys (قابلية التوسع والتكيف للوحدات النمطية)

- USB، واجهة محيطية

- دعم التطبيقات المخصصة للمستخدم ضمن بيئة تعدد المهام الخاصة بعنصر التحكم

- واجهة انحناء المستشعر وتصحيحه

- برنامج Profile-T3D غير المتصل بالإنترنت

نظام DA66S

- وضع برمجة شاشة اللمس الرسومية ثنائية الأبعاد

- تمثيل الآلة ثلاثية الأبعاد في المحاكاة والإنتاج

- شاشة TFT ملونة عالية الدقة مقاس 24 بوصة

- توافق Delem Modusys (قابلية التوسع والتكيف للوحدات النمطية)

- USB، واجهة محيطية

- دعم التطبيقات المخصصة للمستخدم ضمن بيئة تعدد المهام الخاصة بعنصر التحكم

- واجهة انحناء المستشعر وتصحيحه

- برنامج Profile-S2D غير المتصل بالإنترنت

نظام DA69S

- وضع برمجة شاشة اللمس الرسومية ثلاثية الأبعاد وثنائية الأبعاد

- التصور ثلاثي الأبعاد، بما في ذلك التمثيل الآلي ثلاثي الأبعاد، في المحاكاة والإنتاج

- شاشة TFT ملونة عالية الدقة مقاس 24 بوصة

- توافق Delem Modusys (قابلية التوسع والتكيف للوحدات النمطية)

- USB، واجهة محيطية

- دعم التطبيقات المخصصة للمستخدم ضمن بيئة تعدد المهام الخاصة بعنصر التحكم

- واجهة انحناء المستشعر وتصحيحه

- برنامج Profile-S3D غير المتصل بالإنترنت

التعبئة والتسليم

كن أول من يراجع “Genius CNC Servo Press Brake 6+1 Axis With Laser Check” إلغاء الرد

فرامل هيدروليكية CNC Servo

$17,500.00

المراجعات

لا توجد مراجعات حتى الآن.