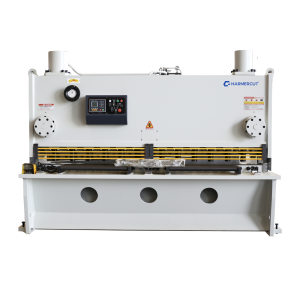

Hydraulische Schwenkbalkenschere

$9,700.00

Typ: Schwingbalkenschere

Modell: QC12K-6×3200

Steuerungssystem: E21S

Dimension: 3840x1710x1620mm

Gewicht: 5600 kg

Kategorie: Hydraulische Schermaschine

Voraussichtliche Lieferung:28 Tage

Standardspezifikation

E21S Steuerungssystem

- Steuerung der hinteren Anschlagposition. Der Scherwinkel kann gesteuert werden. Das Scherspiel kann gesteuert werden.

- Die Schnittzeit ist steuerbar. Intelligente Positionierungsfunktion.

- Einweg- und Zweiweg-Positionierungsfunktion, wodurch das Spiel der Leitspindel effektiv eliminiert wird.

- Materialausweichfunktion. Automatische Referenzpunktsuchfunktion.

- Parameter: Ein-Klick-Backup- und Wiederherstellungsfunktion. Schnellzugriffsfunktion für die Standortbestimmung.

- 40 Speicherplatz für Mehrschrittprogramme, jedes Programm hat 25 Arbeitsschritte.

- Ausschaltschutzfunktion

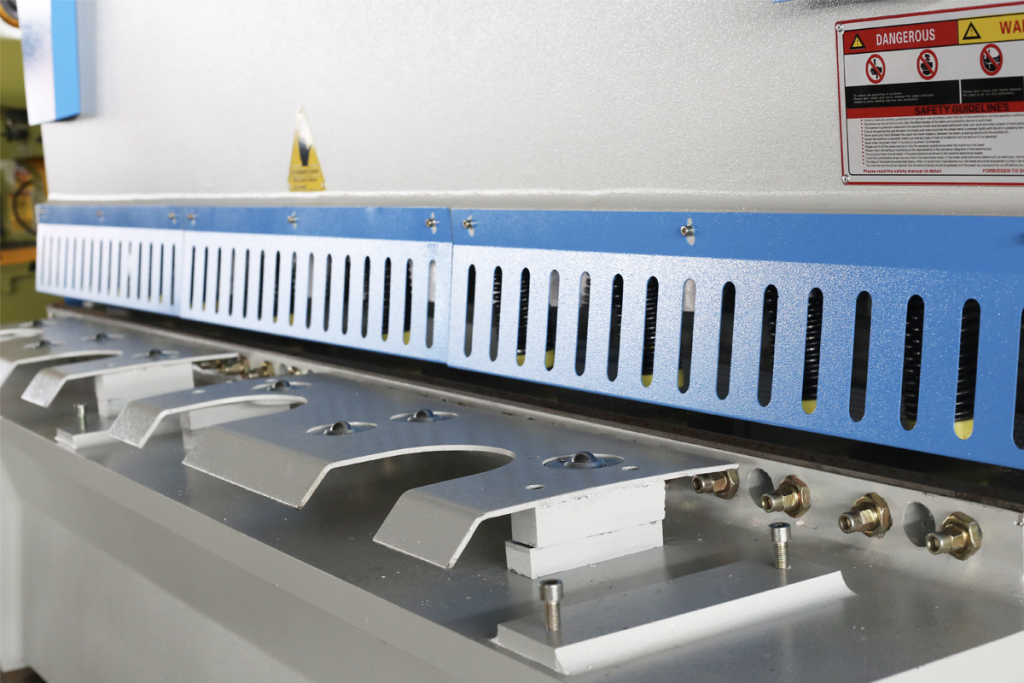

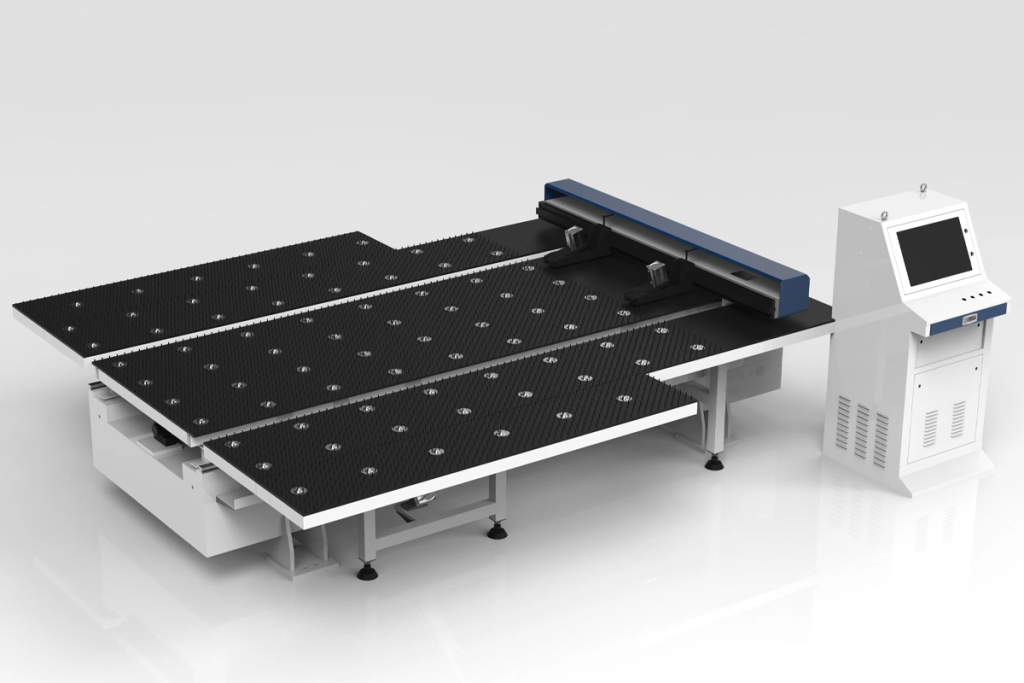

Kugelroll-Arbeitstisch

- Erleichterung der Bewegung von Platten

Reibungsreduzierung: Der Kugelarbeitstisch ersetzt die herkömmliche Gleitreibung durch das Rollen zahlreicher Kugeln und reduziert so die Reibung zwischen Platte und Arbeitstisch deutlich. Während des Schervorgangs können Bediener die Platte zur Positionsanpassung leichter verschieben. Besonders bei schwereren oder größeren Platten ist der arbeitssparende Effekt deutlich spürbar.

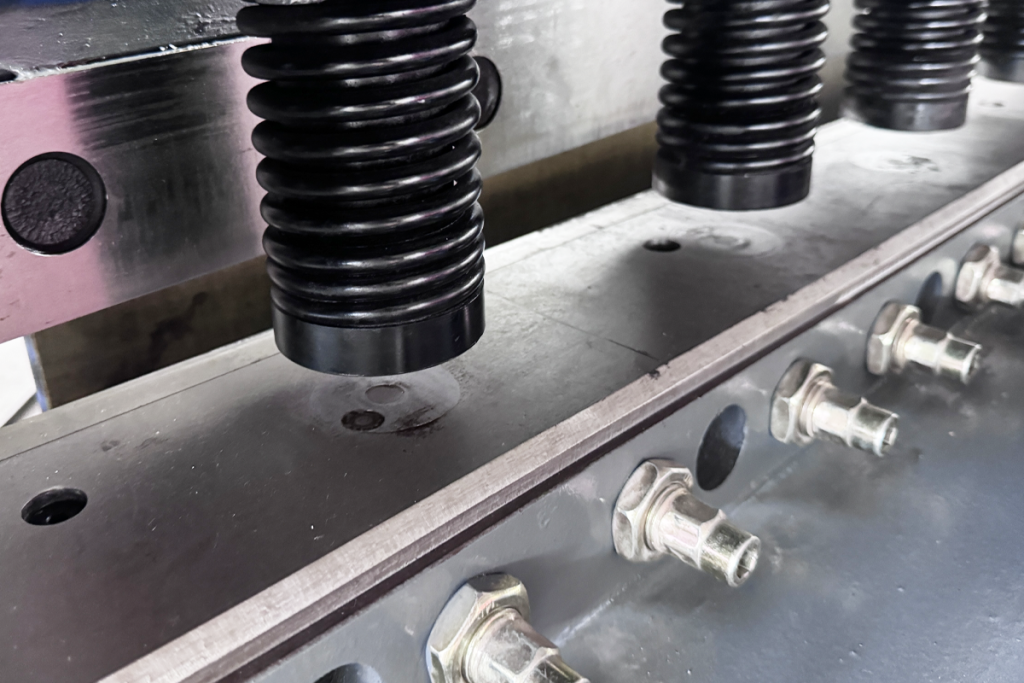

Presszylinder

- Das untere Ende des Presszylinders besteht aus nichtmetallischem Material, das eine gewisse Elastizität und einen großen Reibungskoeffizienten aufweist.

- Beim Schneiden des Blechs kann das Presspolster in engem Kontakt mit der Materialplatte stehen, um ausreichend Reibung zu erzeugen und so ein Erschüttern der Platte während des Schervorgangs wirksam zu verhindern.

Hydraulikventil

- Das integrierte Hydrauliksystem der Rexroth GmbH wird übernommen. Das Hydrauliksystem reduziert die Installation von Rohrleitungen, überwindet das Phänomen des Öllecks, verbessert die Arbeitsstabilität der Werkzeugmaschine und macht das Erscheinungsbild der Werkzeugmaschine schön und einfach

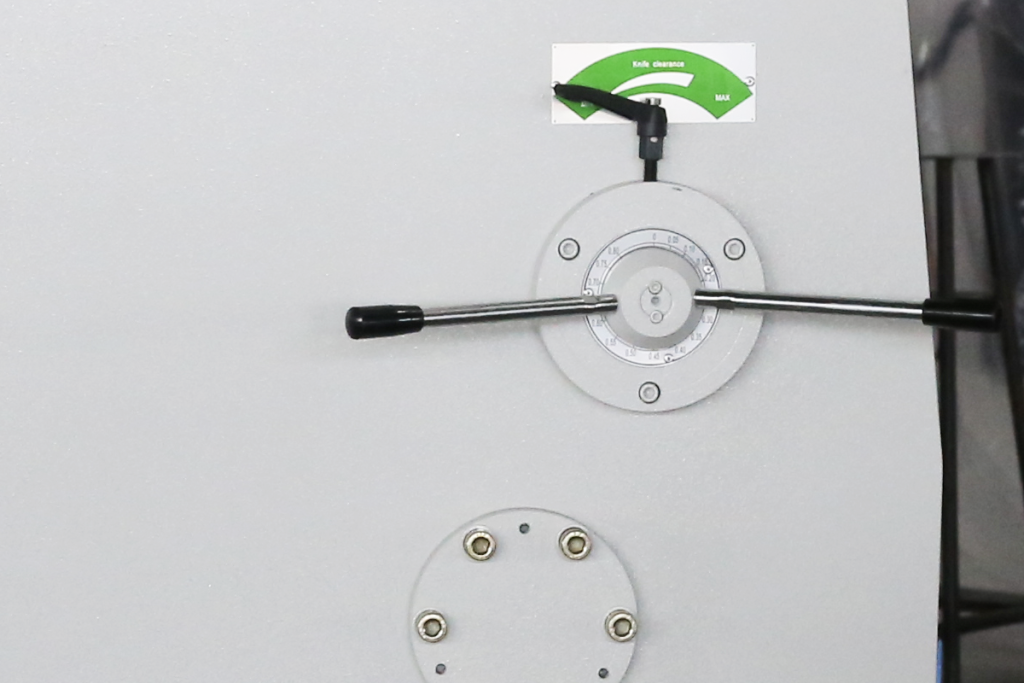

Schermesserspalteinstellung

- Um eine bessere Schneidleistung zu erzielen, passen Sie den Abstand der Schneidklingen manuell an die Schnittdicke des Metallblechs an.

Scherklinge

- Hohe Härte: Hergestellt aus hochwertigem legiertem Stahl, um Verschleißfestigkeit beim langfristigen Schneiden zu gewährleisten.

- Scharfe Kante: Präzise geschliffene Kanten garantieren saubere, gratfreie Schnittflächen der Werkstücke.

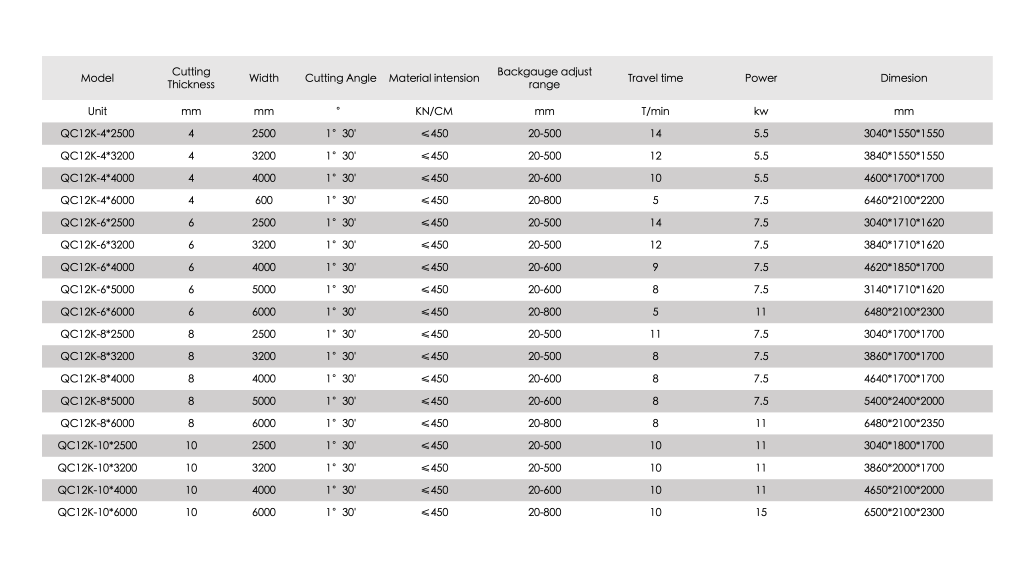

Technische Spezifikation

Optionale Konfiguration

DAC360T Scherkomfort auf Knopfdruck

- Vielseitige Scherensteuerungslösung mit umfassender Funktionalität

- Die DAC-360T-Steuerung bietet eine benutzerfreundliche und vielseitige Touch-Steuerung für Scheren. Dank modernster Elektronik lassen sich bei Bedarf mehrere Hinteranschlagachsen, Schnittwinkel, Hublänge und Spaltweite steuern. Neben der Hinteranschlagsteuerung berechnet die DAC-360T automatisch die erforderlichen Einstellungen für Schnittwinkel und Spaltweite abhängig von Materialeigenschaften und -dicke. Die Hublänge wird basierend auf der benötigten Schnittlänge optimiert und steigert so die Produktivität.

Servo-Frontfütterungsplattform

- Die Größe und Dicke der Platte werden individuell vom Kunden festgelegt.

Betriebsgenauigkeit von 10 mm, geeignet für große Schermengen.

Personalsparende, hocheffiziente Funktionen

Sicherheitsvorrichtung Lichtvorhang

- Der integrierte Lichtvorhang maximiert die Sicherheit des Bedieners, indem er die Maschine automatisch stoppt, wenn eine Störung erkannt wird.

Verpackung und Lieferung

Seien Sie der Erste, der „Hydraulic Swing Beam Shearing Machine“ bewertet. Antworten abbrechen

Hydraulische Blechschneidemaschine ...

$17,000.00

Hydraulische Guillotine-Schere ...

$13,000.00

Bewertungen

Es gibt noch keine Bewertungen.