No hay productos en el carrito.

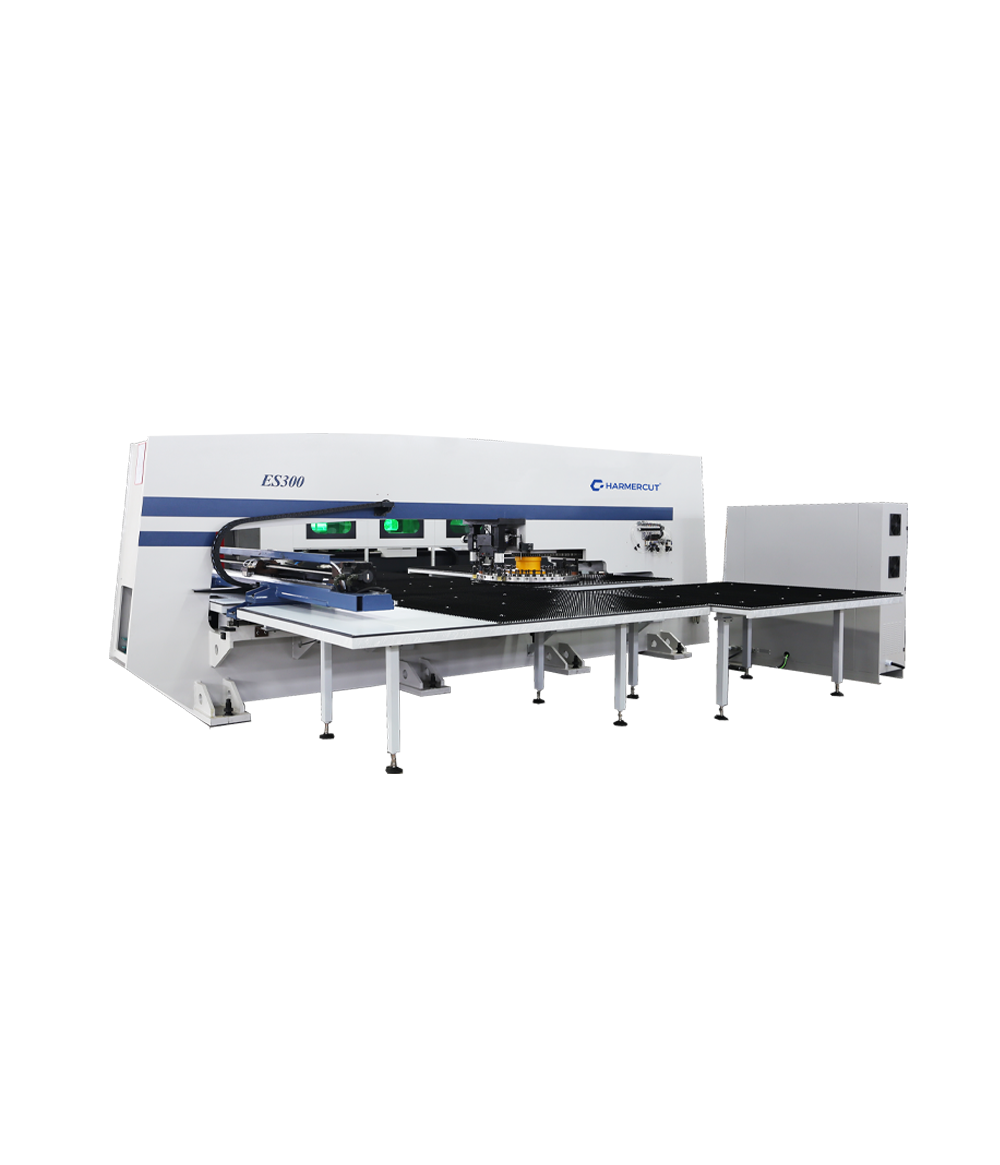

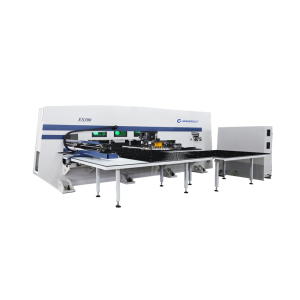

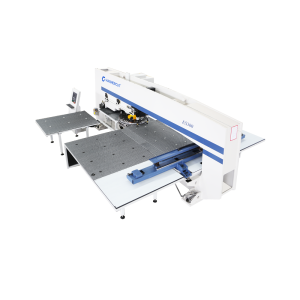

Máquina punzonadora de torreta CNC

$78,571.00

Calificado con 5.00 de 5 según la calificación del cliente 1

(1 valoración de cliente)

Diseño único de cuerpo de alta rigidez, rendimiento estable.

La potencia de perforación principal adopta un servomotor totalmente eléctrico, de alta eficiencia y ahorro de energía.

Puede realizar punzonado, corte, conformado, laminado, rotulación y otros procesos.

La transmisión mecánica y los componentes eléctricos y neumáticos son marcas importadas.

Categoría: Máquina perforadora

Entrega estimada:3 días

Características de la punzonadora de torreta CNC

La nueva generación de punzonadoras de torreta CNC es una punzonadora de torreta de bajo consumo energético y alta eficiencia con bajos costos ambientales y de mantenimiento, que se puede configurar en 30 toneladas.

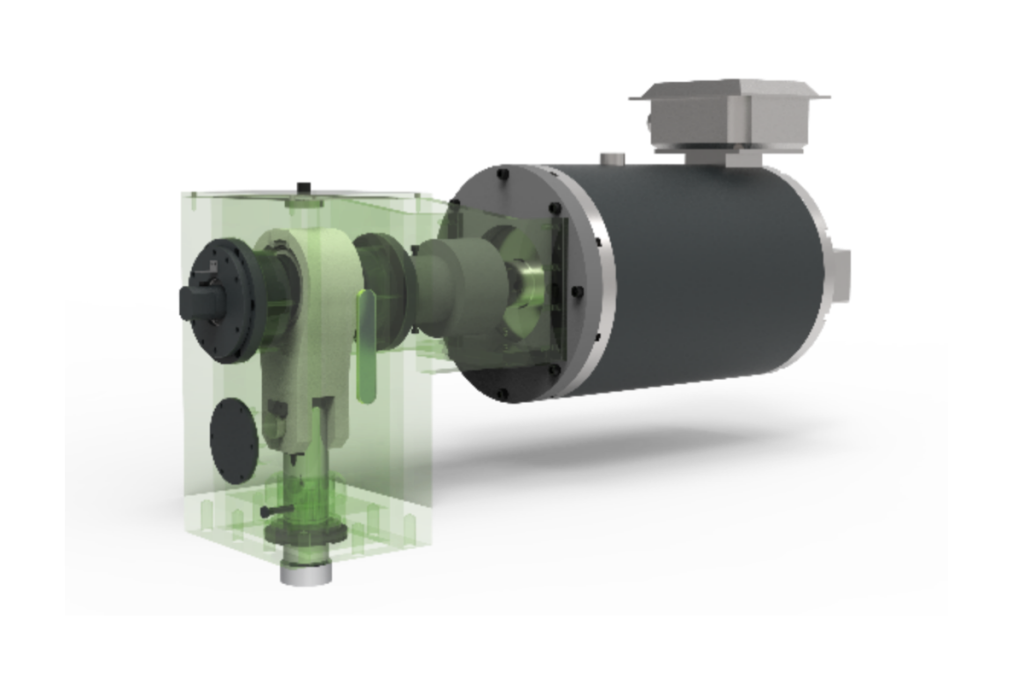

La fuerza de perforación proviene del servomotor principal, que transmite la fuerza mediante una biela accionada directamente, esta estructura de transmisión conserva la ventaja del método de transmisión mecánica, es madura y confiable. El espacio mecánico eliminado permite una alta precisión de conducción, bajo nivel de ruido y características de larga vida útil.

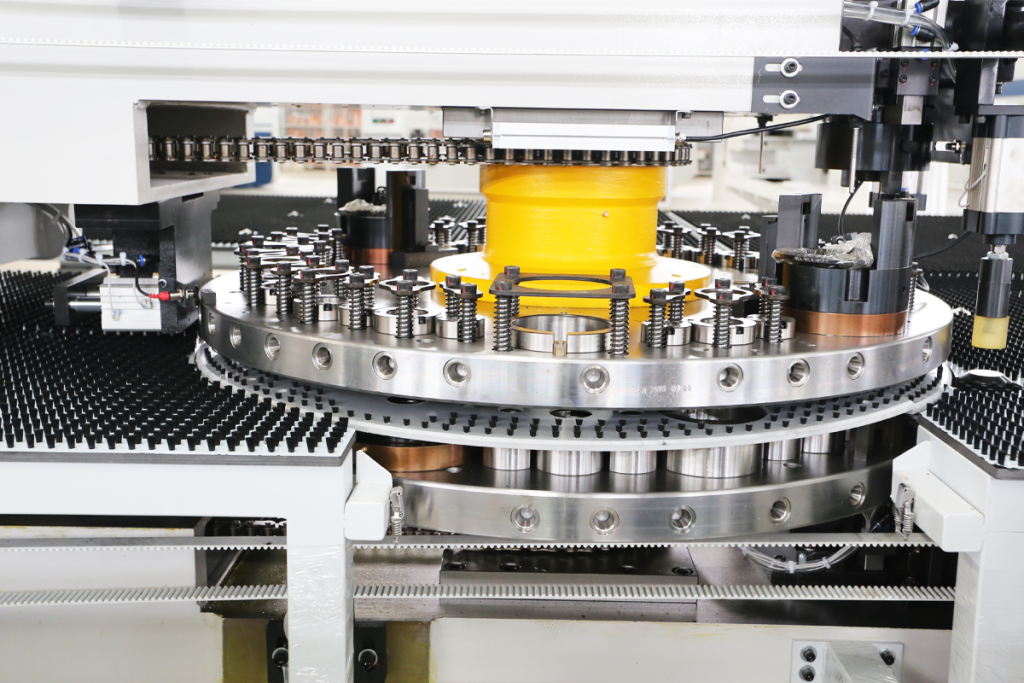

La torreta puede realizar cortes de punzón, conformado, laminado, moldeado, etc. Cuenta con un servomotor inteligente y componentes Rexroth fabricados en Alemania. Cuenta con una torreta de mosaico de 32 estaciones, antidesgaste y sistema de control CNC Rexroth Indrawork Mix.

Configuraciones detalladas

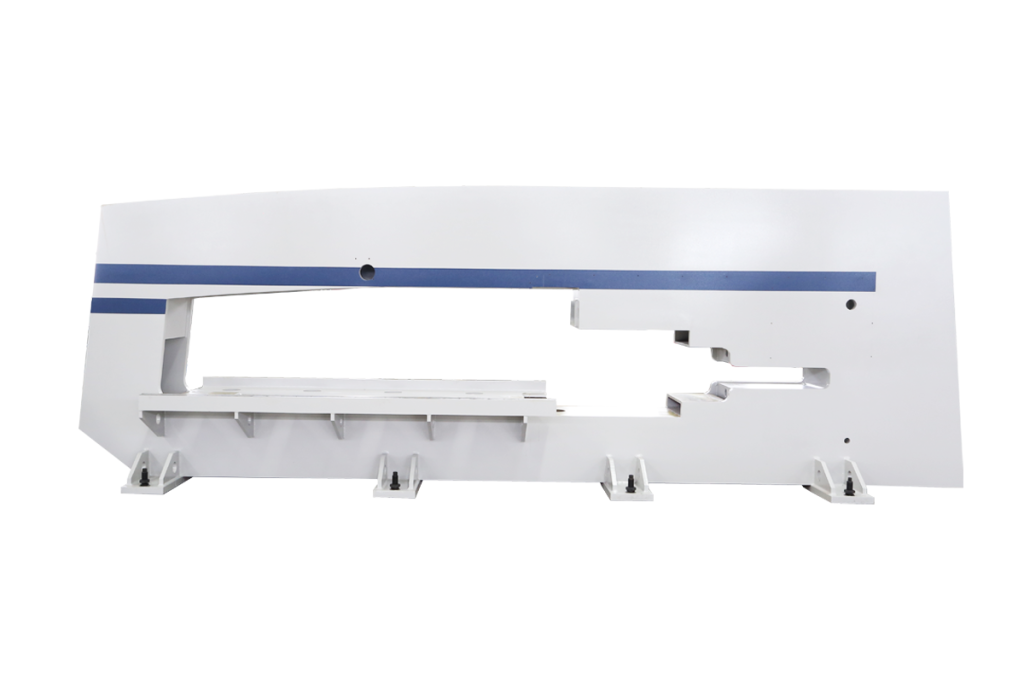

Marco

- Marco de prensa de soldadura integral cerrado tipo O especial para prensa punzonadora servo. Estructura de soldadura holística, alivio de tensión del tratamiento de templado.

- La fuerte rigidez y el alto tonelaje garantizan una precisión estable durante mucho tiempo, extienden la vida útil de la máquina y las herramientas y mejoran la precisión de posicionamiento, la confiabilidad y la durabilidad.

Tecnología de transmisión servoy

- Tecnología electrónica completa, sin ningún componente hidráulico involucrado.

- Transmisión principal con servoaccionamiento directo, tonelaje.

- Tipo de tanque de aceite sellado, buena lubricación, baja generación de calor,

Instalación de insertos. Con nervadura rodante, rotulación, orificio de desmontaje, estiramiento,

persiana, ángulo de recorte y corte, función de conformado.

Estación indexada completamente automática

- Estructura única de engranaje helicoidal para garantizar la precisión de la transmisión bidireccional positiva y negativa.

- Transmisión por correa síncrona de importación única para garantizar la sincronización entre subida y bajada.

Abrazaderas neumáticas flotantes

- Las abrazaderas neumáticas flotantes reducen la deformación de la placa.

- La función de autoprotección no crea zonas muertas al perforar la hoja.

- La abrazadera flota automáticamente al sujetar la placa, lo que resulta conveniente para la abrazadera de la placa.

- Descarga automática al regresar la pinza

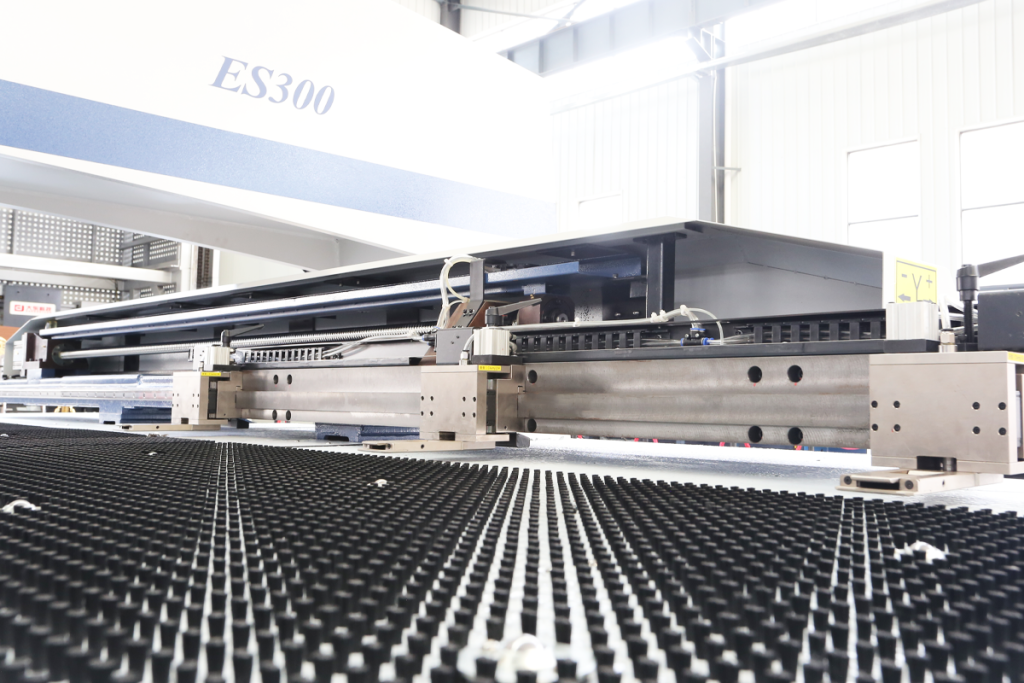

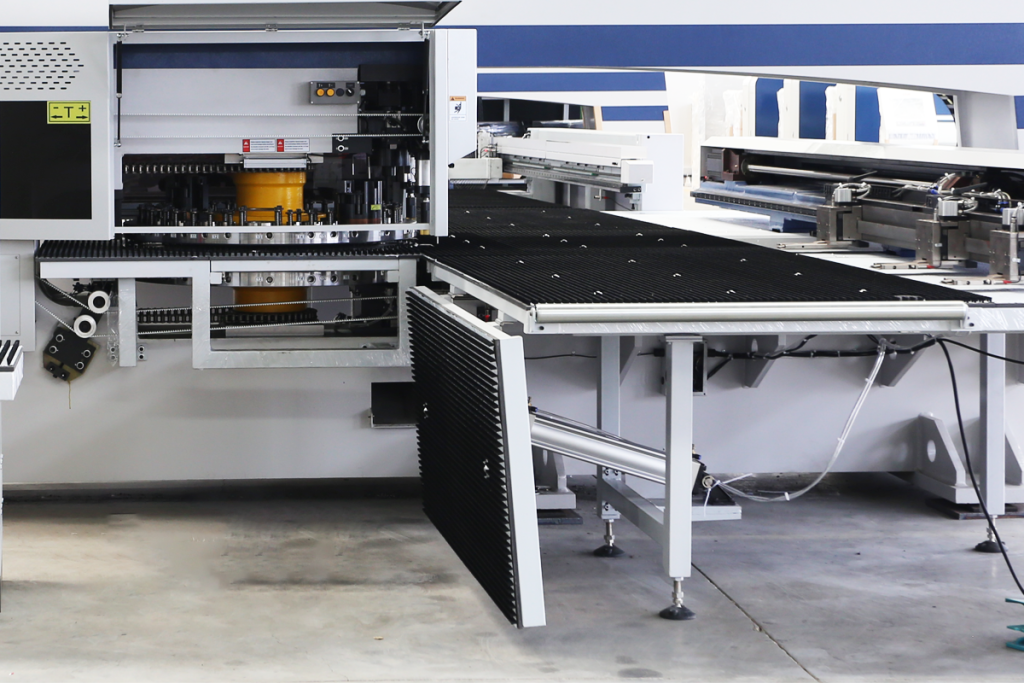

Mesa de trabajo

- La superficie de la mesa de trabajo con cepillo duro y bola de acero, para reducir el ruido durante el trabajo y proteger la superficie de la chapa.

- Diseño de mesa de trabajo sin costuras para evitar colisiones durante el movimiento de la chapa.

- Diseño de mesa plegable, control automático de plegado de plataforma auxiliar lateral, fácil cambio de herramientas.

- Diseño de borde de aluminio, borde lateral de aluminio,

Proteger la superficie de la mesa de trabajo contra el desgaste. - Rodillo auxiliar de carga lateral, fácil de cargar la placa.

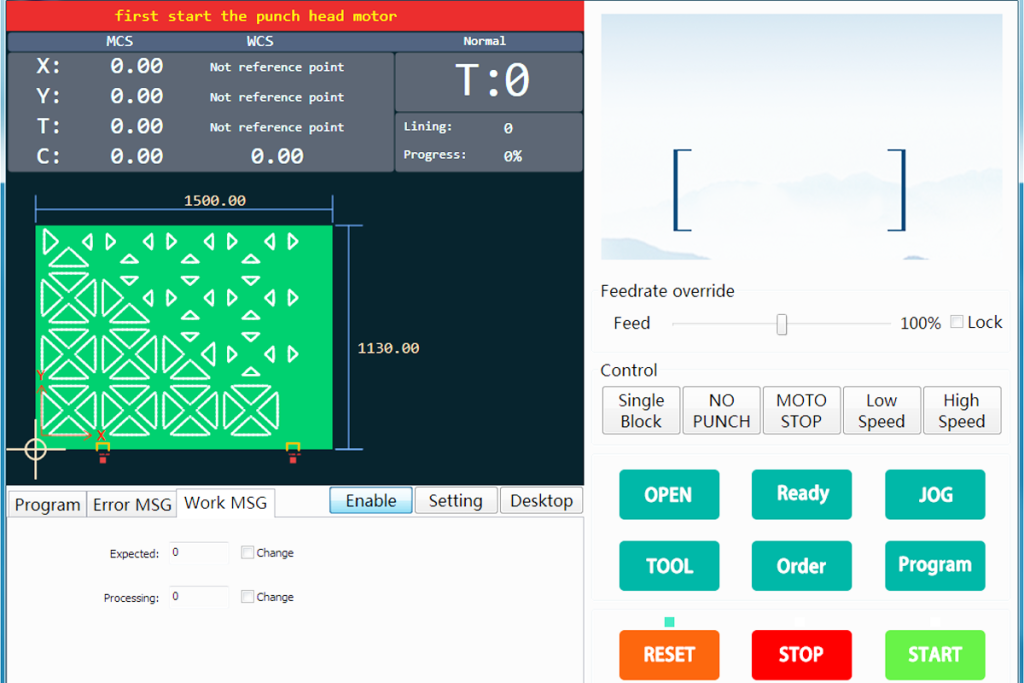

Sistema de control IDEAL PARA EL OPERADOR

Comunicación en red, el software permite una variación de velocidad infinita. Visualización en tiempo real de gráficos de mecanizado, interfaz intuitiva y fácil de usar. Con una sola tecla para volver al punto de referencia, se pueden establecer posiciones de carga clave.

La altura de precarga del punzón se ajusta automáticamente según el espesor de la placa. Permite configurar alta precisión, velocidad extrema, normal y diversos modos de procesamiento.

Detección automática de la posición de la abrazadera. Función de procesamiento del punto de ruptura, función de procesamiento analógico.

Operación con una sola tecla, función de inicio de ciclo.

Cada estación cuenta con su propia área de protección y parámetros de procesamiento independientes. Programación de campo y programación en segundo plano.

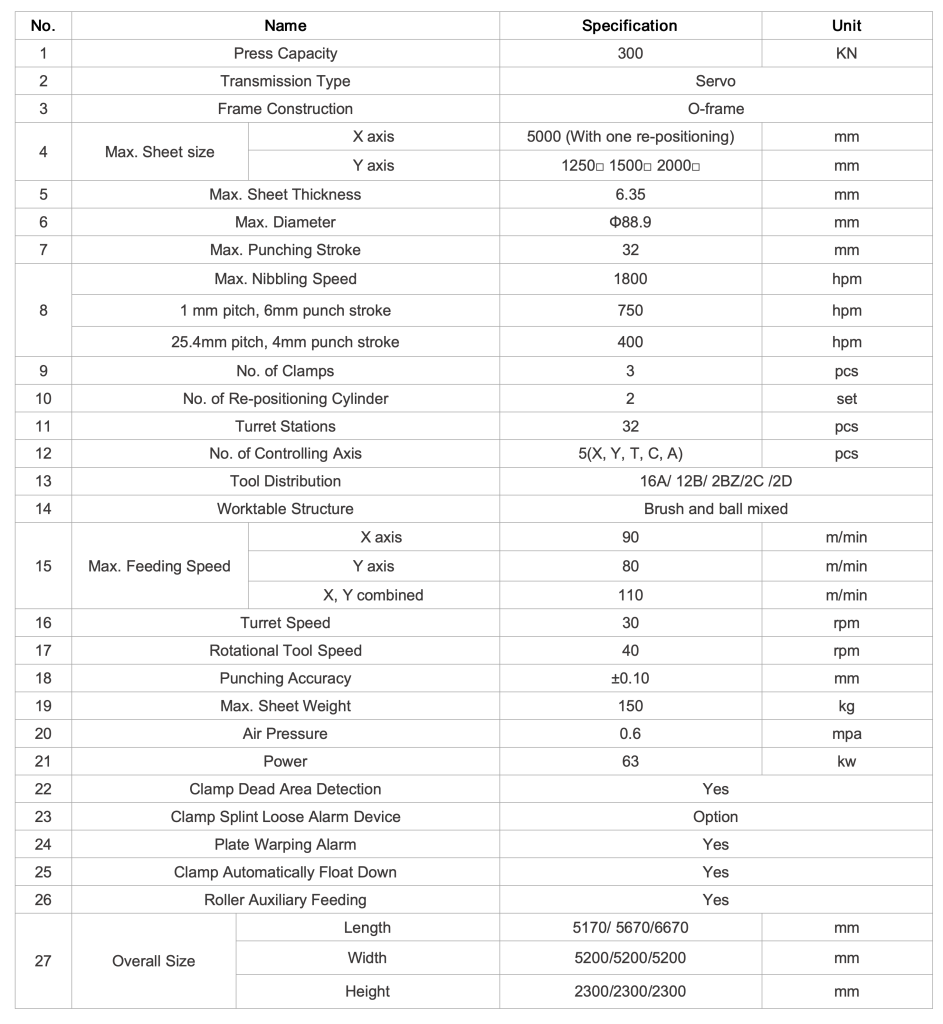

Datos técnicos

Embalaje y carga

5.00

Calificado con 5.00 de 5 según la calificación del cliente 1

Basado en reseñas de 1

Calificado con 5 de 5 según la calificación del cliente 1

1

Calificado con 4 de 5

0

Calificado con 3 de 5

0

Calificado con 2 de 5

0

Calificado con 1 de 5

0

Reseña de 1 para CNC Turret Punching Machine

Añadir una reseña Cancelar la respuesta

Máquina punzante hidráulica

$6,428.00

Prensa neumática de 80 toneladas para...

$18,571.00

rosetyler –

Tempus leo eu aenean sed diam urna tempor. Pulvinar vivamus fringilla lacus nec metus bibendum egetas. Iaculis massa nisl malesuada lacinia integer nunc posuere. Ut hendrerit sempre vel class aptent taciti sociosqu. Ad litora torquent per conubia nostra inceptos himenaeos.