$9,500.00

يكتب: سيرفو كهربائي كامل (برغي مزدوج TBI عالي التحمل)

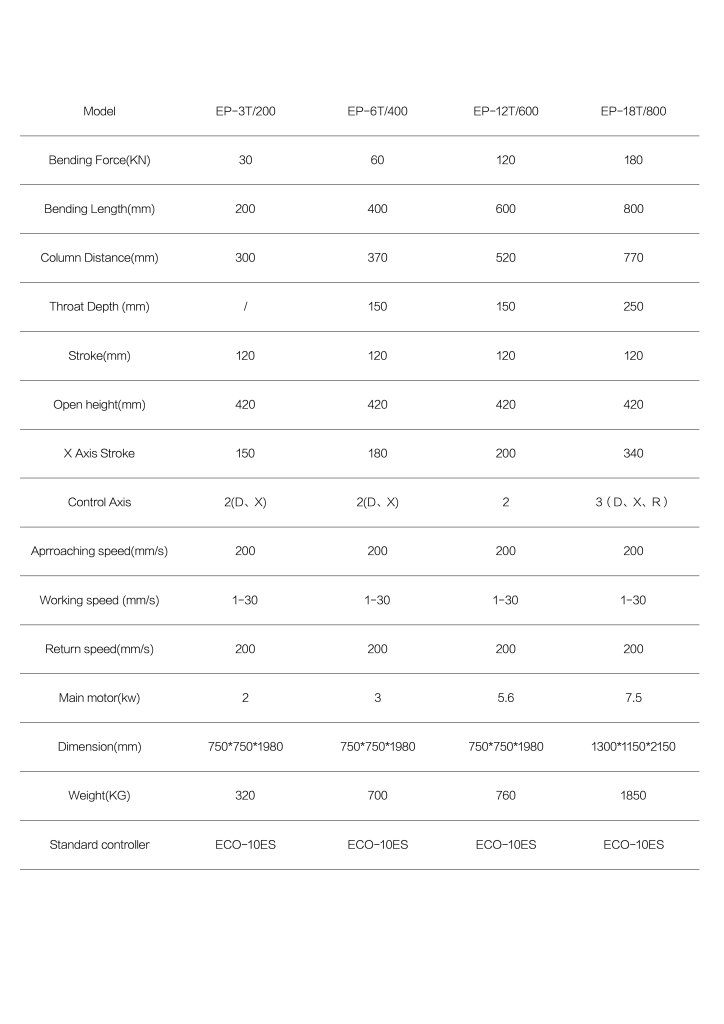

نموذج: EP-12T/600

نظام التحكم: Eco-10ES (ذكي)

محور التحكم: 4 محاور (Y1، Y2، X، R)

البعد:9001 × 900 × 2000 مم

وزن: 870 كجم

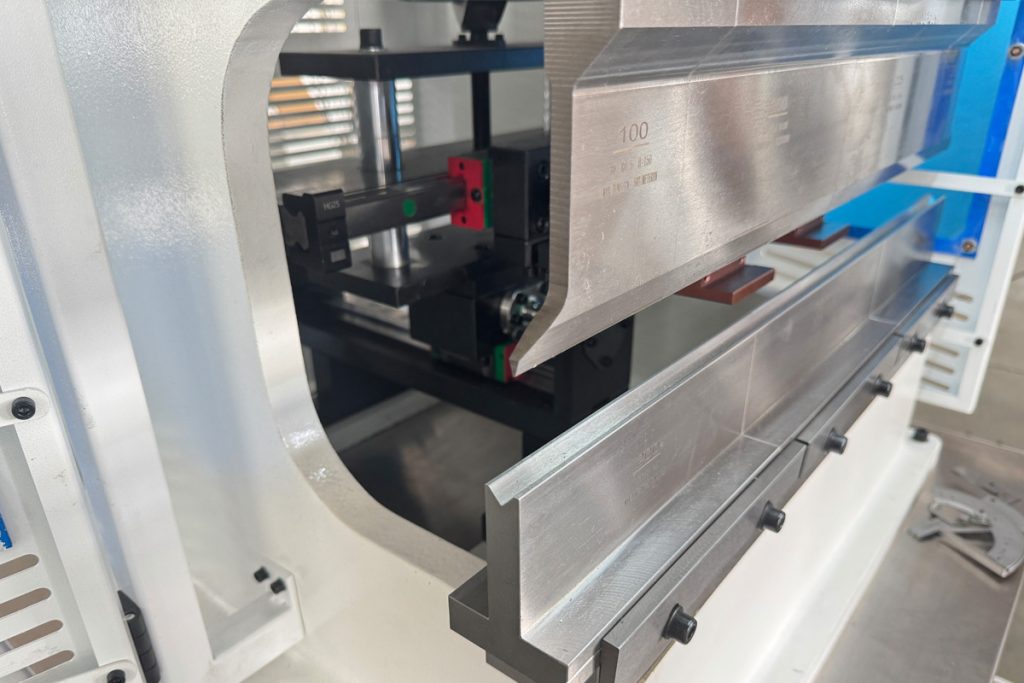

آلة الثني الكهربائية من سلسلة Harmercut EP هي حل ثني غير هيدروليكي مضغوط وسريع ودقيق.يُدار الكبش بمحرك سيرفو عالي التحمل وبرغي كروي عالي الأداء. يجمع هذا المفهوم المبتكر للآلة بين الإنتاجية والدقة والمرونة والموثوقية.

الميزات الرئيسية:

إيكو-10ES

محرك سيرفو

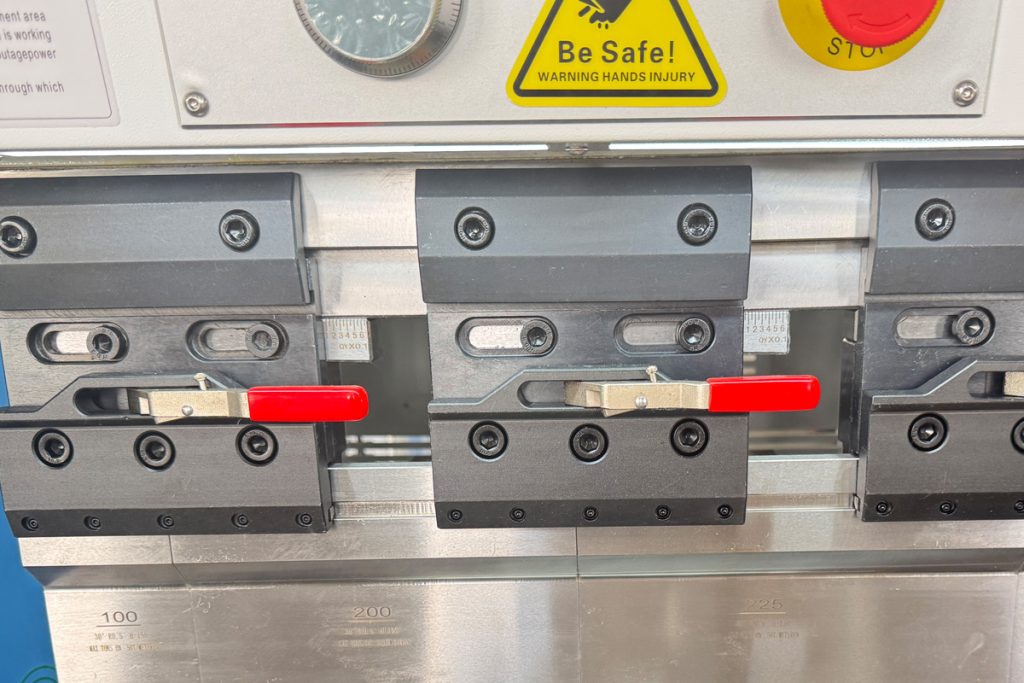

المشبك السريع

أدوات مكابح الضغط

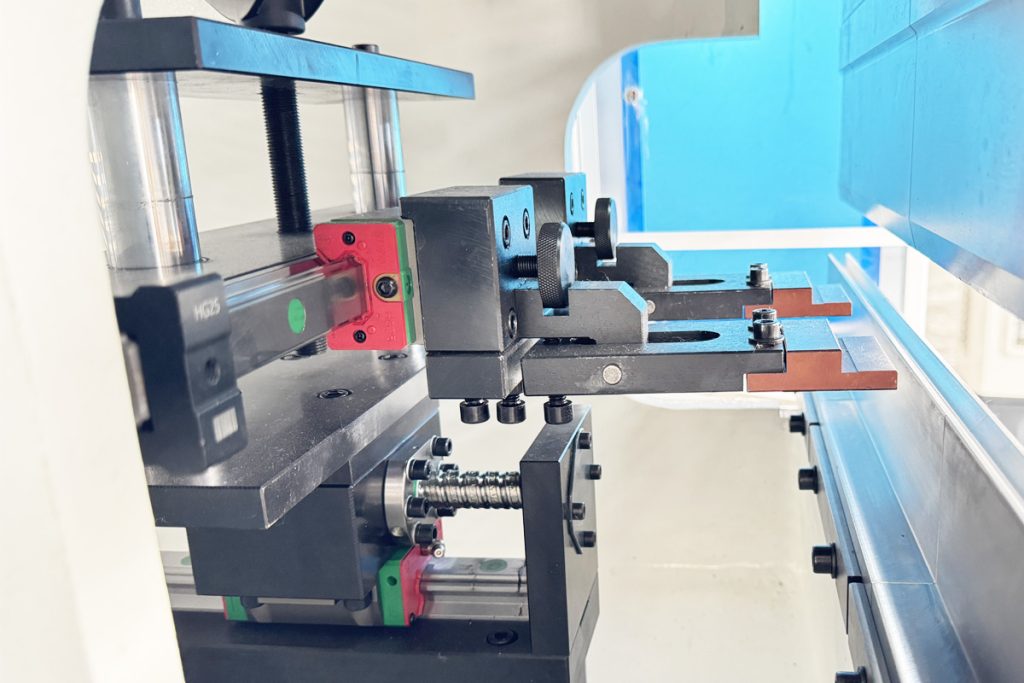

مقياس خلفي متكامل

برغي TBI عالي التحمل

نظام DA53TX

واقي الليزر

$15,000.00

انضم إلى نشرتنا الإخبارية واحصل على عروض حصرية وتحديثات وأخبار Accurl.

المراجعات

لا توجد مراجعات حتى الآن.